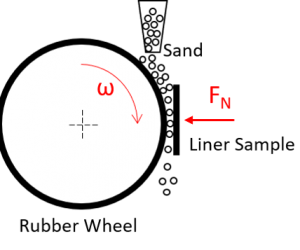

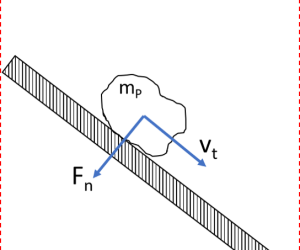

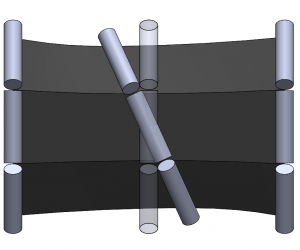

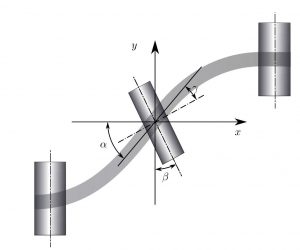

Abrasive Wear in Bulk Material Handling In the field of construction machinery and bulk material handling systems the main cause of equipment failure is the high level of wear and as a result a downtime of the production. This wear occurs especially in the handling of highly abrasive bulk materials and powders. For instance, hard rock materials like granite or minerals like iron ores and […]