This Section aims to provide a general overview of abrasive wear test methods for evaluating wear characteristics of liner samples. Because there are many individual testing procedures, there is no claim to completeness. Instead, the principles are briefly explained, as well as several advantages and disadvantages of general test rig build ups are shown.

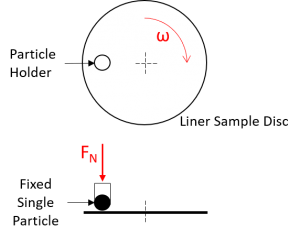

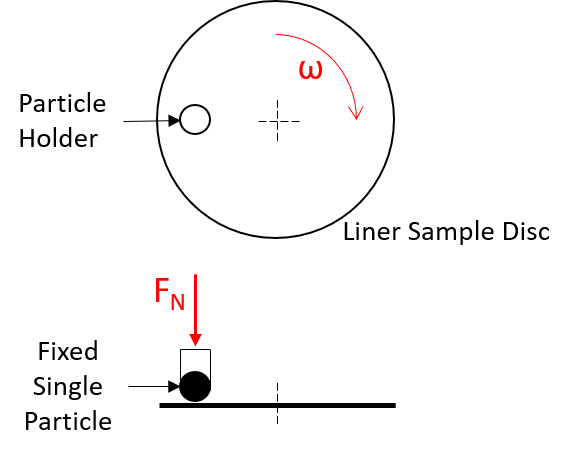

Test Principle:

The particle on disc test is transferred from the classical pin on disc test to determine abrasive wear characteristic of solids. A single particle is fixed to a special holder and a normal force acts on the particle. The disc consists of the liner sample material and rotates at a constant speed.

Advantages:

Disadvantages:

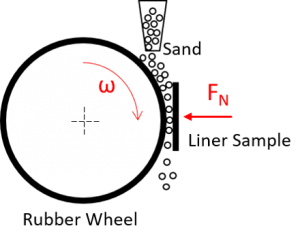

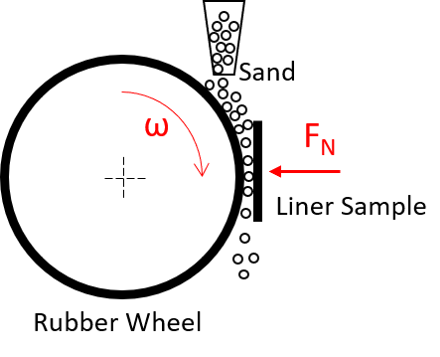

Test Principle:

The wheel has a rubber sheath and rotates with a constant velocity. The bulk material falls due to gravity from a funnel in the gap between the wheel and the liner sample. A normal force acts on the liner sample and press it against the rubber wheel and the bulk material inside the gap. The particles are pressed into the rubber and slide along the liner sample without rotation.

Advantages:

Disadvantages:

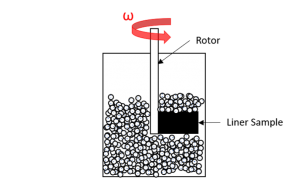

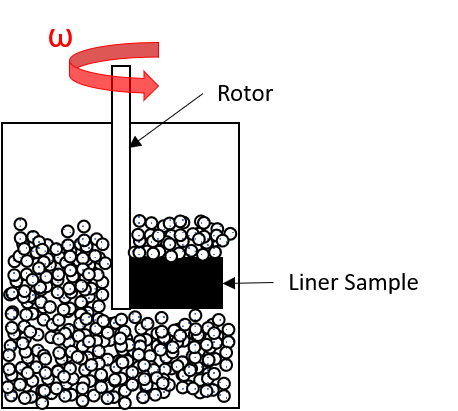

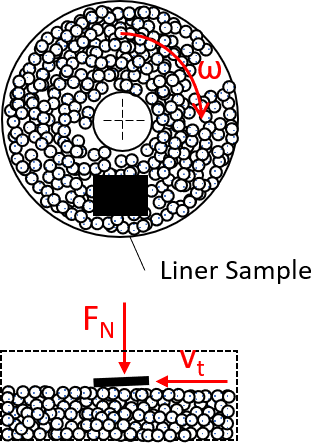

Test Principle:

One or more liner samples are fixed to the end of the rotor. The rotor in placed in a pot filled with bulk material, so that the samples are surrounded by bulk material. For the test the rotor rotates with a defined velocity. Furthermore, samples can be rotated to their own axis to determine different angles. There are also others in which a lid is seated on the bulk material. This can be acted upon with an additional force.

Advantages:

Relatively easy to prepare and use in laboratory scale

Disadvantages:

Superposition of different wear mechanism of sliding and impact wear are possible during testing

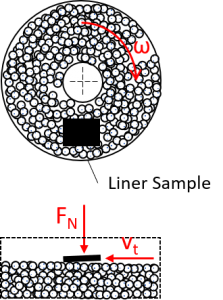

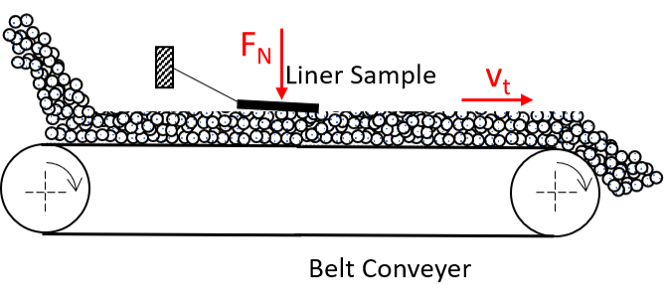

Test Principle:

The linear sliding wear test consists of a belt conveyor that conveys the bulk material under the liner sample with a constant linear velocity. The test enables the investigation of various loads by placing weights on top of the sample (holder). In order to realize a conveying in the cycle, the bulk material is conveyed from the end of the belt conveyor to a bunker at the beginning of the belt via further conveyors.

Advantages:

Free interaction between bulk material and liner sample surface representing close to industrial application case

Disadvantages:

High amount of bulk material is necessary (up to several 100 kg depending on the test rig size)

Test Principle:

The test stand includes a rotating annular trough with outer diameter ranging from one to several meters, in which the bulk material is located. The receiving trough conveys the bulk material bed below the liner sample. Hence, a free interaction between the bulk material and liner sample surface is allowed. The test enables the investigation of various loads and speeds. By inserting an additional plow, even mixing of the bulk material can be made possible during the tests.

Advantages:

Free interaction between bulk material and liner sample surface representing close to industrial application case

Disadvantages:

High amount of bulk material is necessary (up to several 100 kg depending on the test rig size)

Privacy Preference

Privacy Preference

We use cookies on our website. Some of them are essential, while others help us to improve this website and your experience.

Here you will find an overview of all cookies used. You can give your consent to whole categories or display further information and select certain cookies.

Essential cookies enable basic functions and are necessary for the proper function of the website.

| Name | |

|---|---|

| Provider | Owner of this website |

| Purpose | Saves the visitors preferences selected in the Cookie Box of Borlabs Cookie. |

| Cookie Name | borlabs-cookie |

| Cookie Expiry | 1 Year |

Marketing cookies are used by third-party advertisers or publishers to display personalized ads. They do this by tracking visitors across websites.

| Accept | |

|---|---|

| Name | |

| Provider | Google LLC |

| Purpose | Cookie by Google used for website analytics. Generates statistical data on how the visitor uses the website. |

| Privacy Policy | https://policies.google.com/privacy?hl=en |

| Host(s) | |

| Cookie Name | _ga,_gat,_gid |

| Cookie Expiry | 2 Years |

Content from video platforms and social media platforms is blocked by default. If External Media cookies are accepted, access to those contents no longer requires manual consent.

| Accept | |

|---|---|

| Name | |

| Provider | YouTube |

| Purpose | Used to unblock YouTube content. |

| Privacy Policy | https://policies.google.com/privacy?hl=en&gl=en |

| Host(s) | google.com |

| Cookie Name | NID |

| Cookie Expiry | 6 Month |