The training is helt in a Online-Webinar consisting of three modules. The training content will include a fundamental understanding of the DEM and the necessary steps required to perform physical correct simulations. The training will cover the complete workflow of a simulation project as well as the state of the art bulk material calibration.

The DEM Training will be performed as a webinar. The three modules will cover the basic steps which need to be performed to do a reliable and verified simulation using the discrete element method. The modules are divided by their topic. Each module will contain a 90 min presentation and a 30 min discussion and questions. The modules may be performed on different days, to give the attendees time to try out the new gained knowlege.

After the training the attendees will be able to perform simulations with physically correct parameters which show a very high congruence to real life experiments. It is recommended to have a Liggghts installation ready for personal usage during modules two and three.

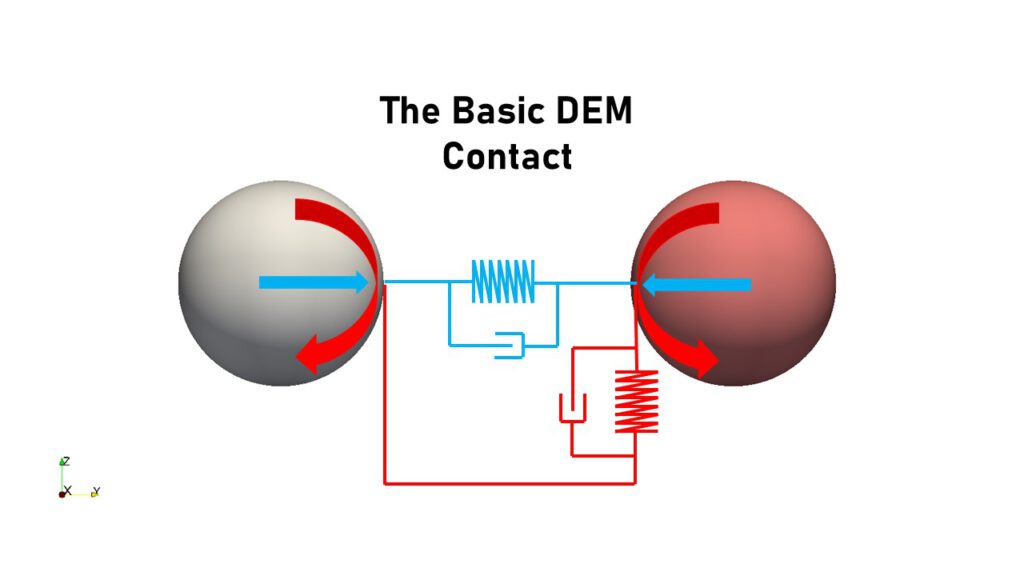

During the first module the basics of the DEM including the mathematical background will be explained. This module is important to gain a better understanding of the processes during the computation of a discrete particle problem. This will give the attendees the chance to understand possible modeling errors and computational problems.

The module includes:

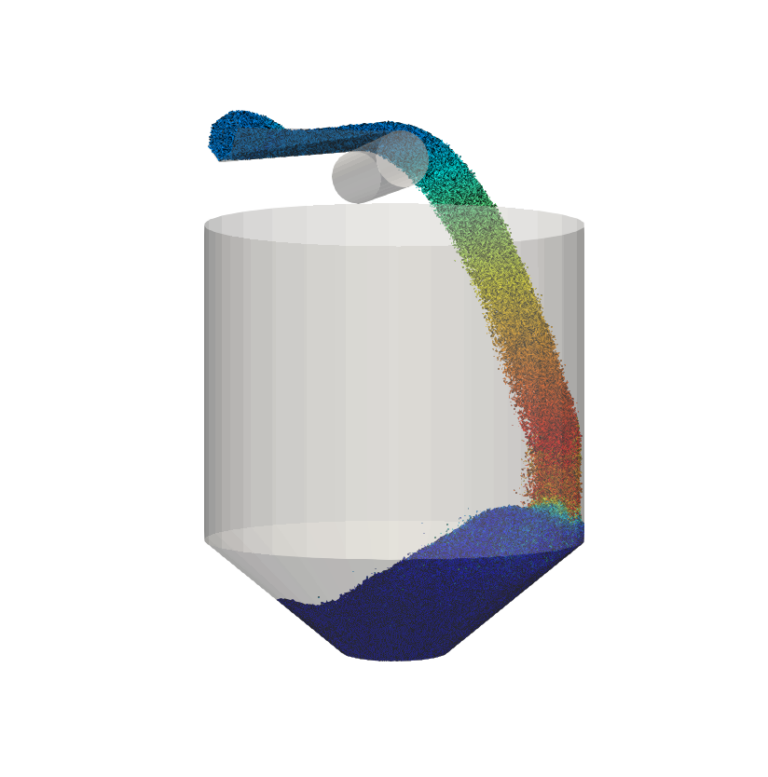

The second module gives the attendees the chance to see how the basics from module one are used to do a simulation of a belt conveyor loading free flowing bulk material into a hopper. The input script will be handed over to the attendees. The module includes the following functions of the DEM-software Liggghts.

The module includes:

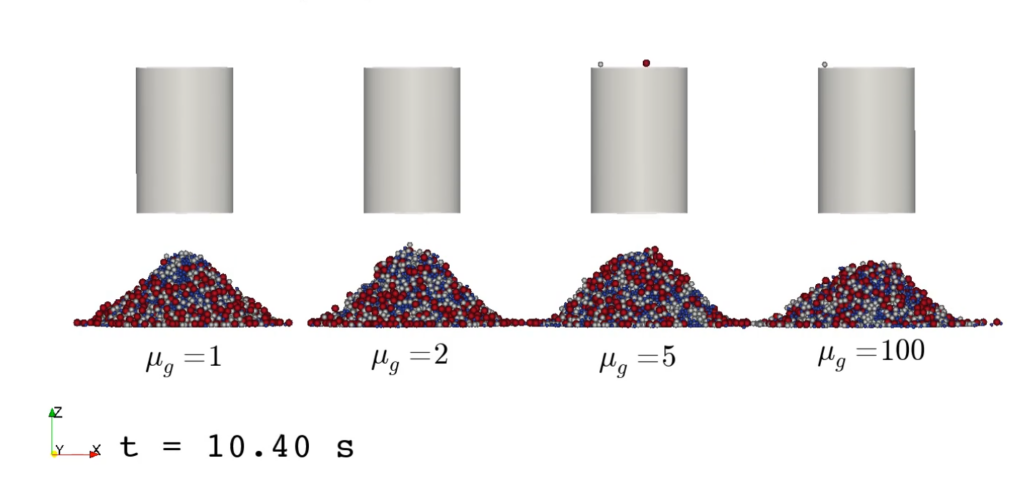

The third module will focus on the measurement and calibration of bulk material properties. Therefore, a calibration of a sample of bulk material will be shown. The laboratory experiments for the calibration will be presented and a Liggghts script for a basic calibration using the “angle of repose” will be explained.

The module includes:

Privacy Preference

Privacy Preference

We use cookies on our website. Some of them are essential, while others help us to improve this website and your experience.

Here you will find an overview of all cookies used. You can give your consent to whole categories or display further information and select certain cookies.

Essential cookies enable basic functions and are necessary for the proper function of the website.

| Name | |

|---|---|

| Provider | Owner of this website |

| Purpose | Saves the visitors preferences selected in the Cookie Box of Borlabs Cookie. |

| Cookie Name | borlabs-cookie |

| Cookie Expiry | 1 Year |

Marketing cookies are used by third-party advertisers or publishers to display personalized ads. They do this by tracking visitors across websites.

| Accept | |

|---|---|

| Name | |

| Provider | Google LLC |

| Purpose | Cookie by Google used for website analytics. Generates statistical data on how the visitor uses the website. |

| Privacy Policy | https://policies.google.com/privacy?hl=en |

| Host(s) | |

| Cookie Name | _ga,_gat,_gid |

| Cookie Expiry | 2 Years |

Content from video platforms and social media platforms is blocked by default. If External Media cookies are accepted, access to those contents no longer requires manual consent.

| Accept | |

|---|---|

| Name | |

| Provider | YouTube |

| Purpose | Used to unblock YouTube content. |

| Privacy Policy | https://policies.google.com/privacy?hl=en&gl=en |

| Host(s) | google.com |

| Cookie Name | NID |

| Cookie Expiry | 6 Month |