In the construction and calculation of a belt conveyor the first step is the calculation and determination of the general size of the conveyor. If bulk material should be conveyed from one place to another the daily mass flow is often given from other parameters of the plant.

The conveyor system is basically calculated by these two values. The mass flow rate is important for the calculation of the power consumption, the volume flow rate for the general size of the needed conveyor.

After the determination of the mass flow rate which is needed to full fill the task of conveying material the general size of the belt conveyor needs to be defined.

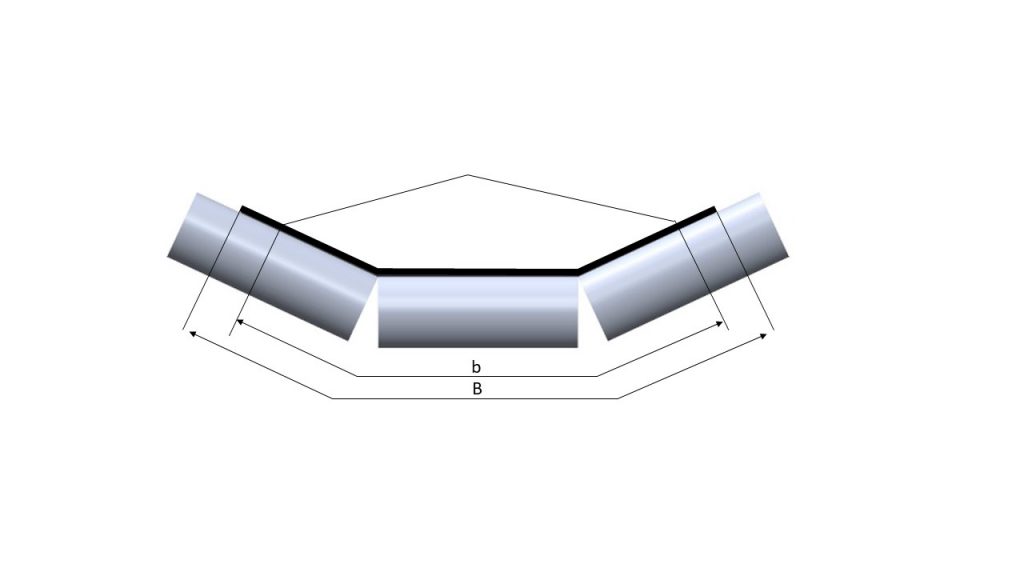

The size includes the belt width, the troughing angle and the size of the idlers. Industrial conveyors for mining and quarry operations have belt width between 650 mm and 3200 mm. The belt width should always be greater than 1.2x size of the biggest particle.

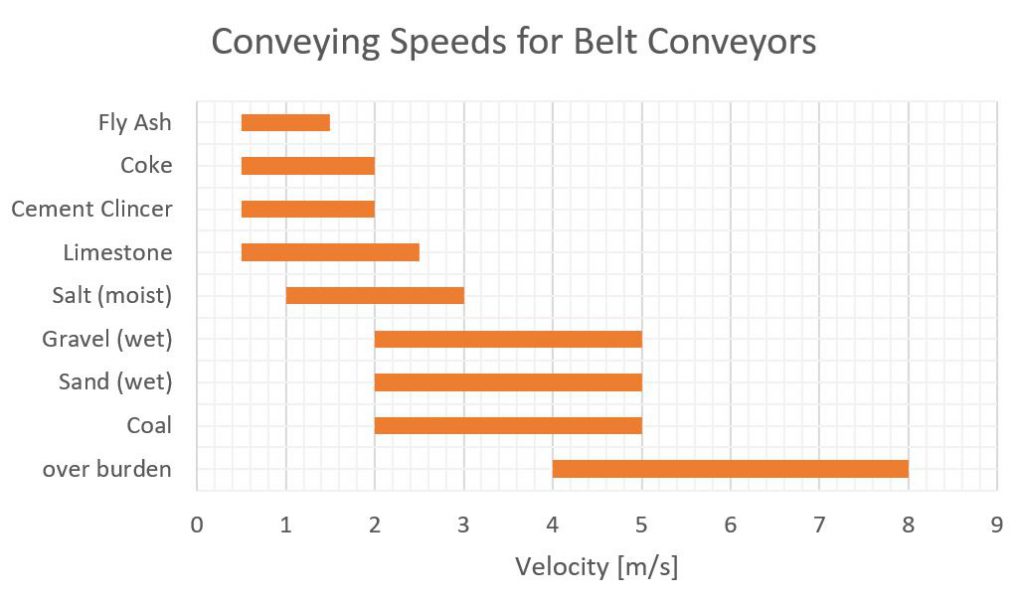

With an increasing belt velocity the belt conveyor becomes more economically because it can be built with in smaller sizes. For standard applications the velocity will be between 1.5 m/s and 4 m/s.

Most conveyors have a 3-part troughing with angles in the steps of 25° / 30° / 35°. Deep troughed conveyors can have angles of 40° / 45°. Because of possible belt mistracking the summed up idler length should increase the belt width by 10 – 15%.

The bulk material form a surcharge angle on the belt after it is loaded on top. This angle varies from bulk material to bulk material. Many bulk materials have a dynamic angle of repose of ca. 10° – 15°. The bulk material area on the belt can easily be calculated depending on the size of the belt, the angle of repose and the length of the middle idler. The bulk material should always be loaded 10% less than the width of the belt.

If you want to know the exact shape of the bulk material on the belt, you can use a DEM Simulation of the transfer chute to verify the cross section.

From the cross section it is possible to calculate the volume flow rate be multipliing with the velocity of the belt.

For example for gravel with an angle of repose of 15 ° a belt of 650mm width and identical idlers with a troughing angle of 35° can be loaded with a cross section of material of 0.045 m². If the conveying speed is 1.5 m/s the volume flow rate will be 0.0675 m³/s. The bulk material density of gravel is 2200 kg/m³. The mass flow rate will be in this case 148.5 kg/s, respectively, 535 t/h.

Privacy Preference

Privacy Preference

We use cookies on our website. Some of them are essential, while others help us to improve this website and your experience.

Here you will find an overview of all cookies used. You can give your consent to whole categories or display further information and select certain cookies.

Essential cookies enable basic functions and are necessary for the proper function of the website.

| Name | |

|---|---|

| Provider | Owner of this website |

| Purpose | Saves the visitors preferences selected in the Cookie Box of Borlabs Cookie. |

| Cookie Name | borlabs-cookie |

| Cookie Expiry | 1 Year |

Marketing cookies are used by third-party advertisers or publishers to display personalized ads. They do this by tracking visitors across websites.

| Accept | |

|---|---|

| Name | |

| Provider | Google LLC |

| Purpose | Cookie by Google used for website analytics. Generates statistical data on how the visitor uses the website. |

| Privacy Policy | https://policies.google.com/privacy?hl=en |

| Host(s) | |

| Cookie Name | _ga,_gat,_gid |

| Cookie Expiry | 2 Years |

Content from video platforms and social media platforms is blocked by default. If External Media cookies are accepted, access to those contents no longer requires manual consent.

| Accept | |

|---|---|

| Name | |

| Provider | YouTube |

| Purpose | Used to unblock YouTube content. |

| Privacy Policy | https://policies.google.com/privacy?hl=en&gl=en |

| Host(s) | google.com |

| Cookie Name | NID |

| Cookie Expiry | 6 Month |