When new roads get constructed or renewed the asphalt surface is usually done by using asphalt paving machines. These pavers are constructed to allow a truck to dump the warm asphalt in the front sections. The asphalt then gets conveyed through the machine and falls into the dispenser where screw conveyors spread the warm asphalt sideways.

In this video we want to give an example, what we can learn from this kind of system in a DEM simulation

The first step in any simulation is always the modelelling of the boundary conditions. In this case the structure of the machine was modelled using blender. The size and the parameters of the simulation are not related to the paver in the beginning of this video. It is just a demonstration of the DEM. You can see how the conveyor is bringing bulk material to the dispenser. Screw conveyors are spreading the asphalt sideways. In the simulation the machine is 5 m wide. After 20 seconds the material is spread in the machine enough and the road construction begins. The machine moves forward and the asphalt layer appears out of the back.

By loading the video, you agree to YouTube's privacy policy.

Learn more

At first glance its obvious, that I did not have the correct operation behaviour of the machine, because the ends of the dispenser are with too much bulk material. This is caused by the federate of the screws, the construction velocity of the machine above ground and the volume flowrate of bulk material.

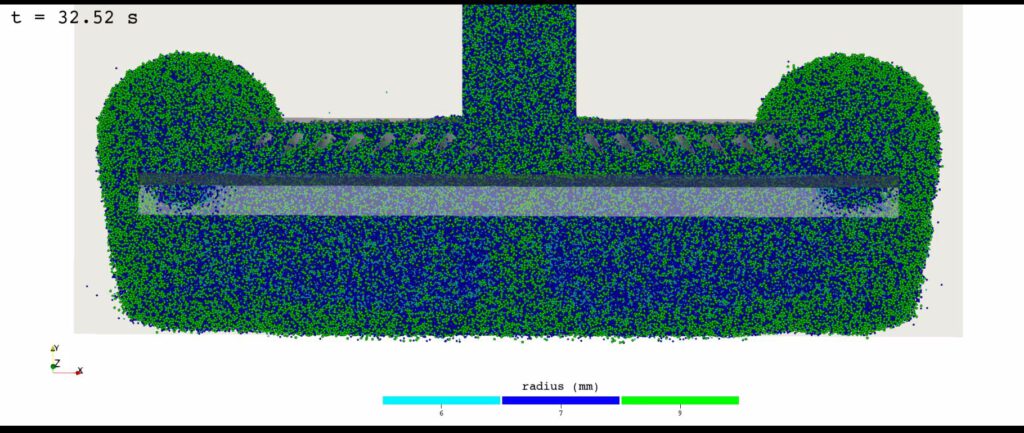

If we have a look to the grain sizes of the asphalt getting conveyed through the machine, we can see a different effect. In the dispenser segregation is occuring. Lager particles are moved to the top of the material flow in the screw conveyors leading to the finer sizes sinking to the bottom. If we have a look to the surface of the road we are constructing, we can see that the coaser particles are located in the middle axis of the paver and at the left and the right edge of our road.

In the middle axis actually the original grain size distribution is build into the street. The edges of the screws are mixing the bulk material and lead to the segration of the fractions. This can be seen in smaller grain sizes left and right from the middle axis.

The longer the conveyor is built the bigger the influence of the segregation. At the edge of our road we can see a lot more of the bigger green particles.

The segregation can be changed by chaining the screw conveyor feed rate, the pitch of the screw, the loading conditions and the construction of the screw like bearings.

Privacy Preference

Privacy Preference

We use cookies on our website. Some of them are essential, while others help us to improve this website and your experience.

Here you will find an overview of all cookies used. You can give your consent to whole categories or display further information and select certain cookies.

Essential cookies enable basic functions and are necessary for the proper function of the website.

| Name | |

|---|---|

| Provider | Owner of this website |

| Purpose | Saves the visitors preferences selected in the Cookie Box of Borlabs Cookie. |

| Cookie Name | borlabs-cookie |

| Cookie Expiry | 1 Year |

Marketing cookies are used by third-party advertisers or publishers to display personalized ads. They do this by tracking visitors across websites.

| Accept | |

|---|---|

| Name | |

| Provider | Google LLC |

| Purpose | Cookie by Google used for website analytics. Generates statistical data on how the visitor uses the website. |

| Privacy Policy | https://policies.google.com/privacy?hl=en |

| Host(s) | |

| Cookie Name | _ga,_gat,_gid |

| Cookie Expiry | 2 Years |

Content from video platforms and social media platforms is blocked by default. If External Media cookies are accepted, access to those contents no longer requires manual consent.

| Accept | |

|---|---|

| Name | |

| Provider | YouTube |

| Purpose | Used to unblock YouTube content. |

| Privacy Policy | https://policies.google.com/privacy?hl=en&gl=en |

| Host(s) | google.com |

| Cookie Name | NID |

| Cookie Expiry | 6 Month |